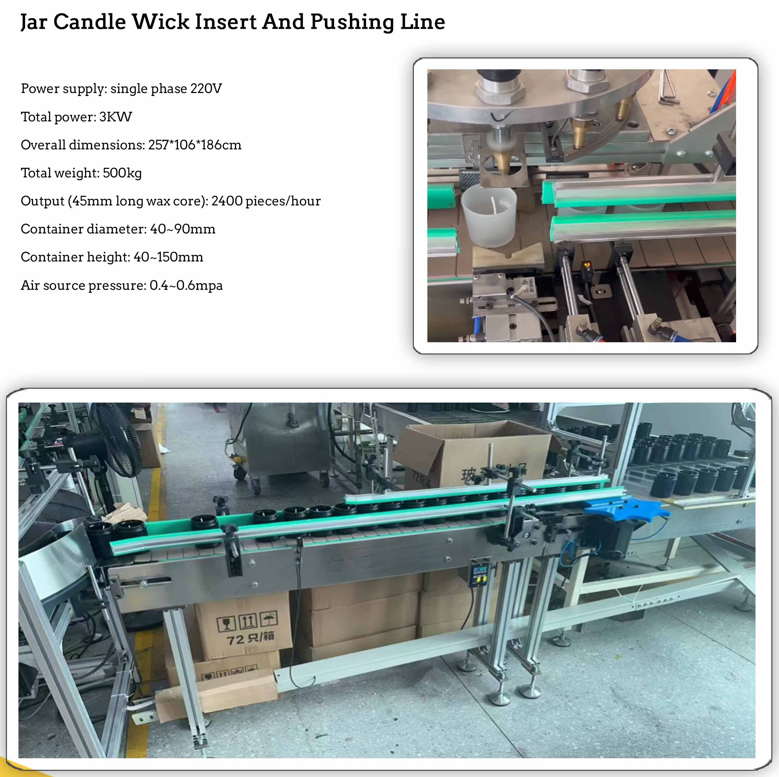

Jar Candle Wick Insert And Pushing Line

Jar Candle Wick Insert And Pushing Line that combines high efficiency, precision, and stability, designed specifically for the core processes of "wick insertion" and "positioning" in glass jar candle production. It completely replaces the traditional inefficient and error-prone manual operations, achieving full automation from empty jar loading to wick insertion, fixation, and precise positioning to the next station (such as the wax filling line).

- GAOWAX

- China

- 15~30days

- 50 Sets per Month

- Information

This is a fully automated production line that combines high efficiency, precision, and stability,

designed specifically for the core processes of "wick insertion" and "positioning" in glass jar candle production.

It completely replaces the traditional inefficient and error-prone manual operations, achieving full automation from empty jar loading to wick insertion, fixation, and precise positioning to the next station (such as the wax filling line).

Jar Candle Wick Insert And Pushing Line Core Functions and Processes:

This production line seamlessly integrates two key steps through a sophisticated mechanical structure and intelligent control system:

Automatic Candle Wick Insertion

Automatic Loading: The system automatically separates and delivers metal wick holders from a vibrating plate or hopper.

Precise Placement: A robotic arm or precision gripper picks up the wick holder and precisely places it in the center of the bottom of the glass jar.

Secure Fixation: Air pressure or mechanical means firmly press the wick holder against the jar bottom, ensuring it will not shift during subsequent processing.

Jar Candle Wick Insert And Pushing Line Automatic Can Body Pushing:

Line Connection: After the wick is inserted, the can is smoothly transferred to the conveyor.

Precise Positioning and Pushing: Once a sensor detects that the can is in place, a pushing mechanism (such as a servo motor-driven pusher or synchronous belt mechanism) accurately pushes the can to the next process line, typically the molten wax filling line, at a preset pace and spacing.

Seamless connection: The entire process is perfectly integrated with the front-end and back-end production lines (such as tank cleaning line, wax filling line, cooling line) to form a smooth continuous production line.